Split Seals

A.W. Chesterton Company Split Seals

Chesterton is the world leader in design innovation of split seals. Our innovative split seals have been used t o seal thousands of process-critical pieces of rotating equipment with exceptional results and many years of leak-free operations.

o seal thousands of process-critical pieces of rotating equipment with exceptional results and many years of leak-free operations.

Chesterton was the first company to offer commercially-viable split seals for plant-wide use, which revolutionized pump sealing across industries. Since that time, we've launched a number of innovative split seal designs now used as a standard by companies around the globe. We offer shaft diameters ranging from 25-914 mm (1-36 in.)

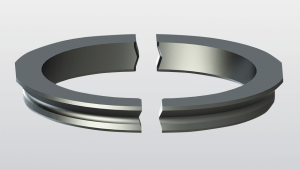

What is a Split Seal?

A split seal has components split into two equal halves which are secured as one unit on the seal shaft. The major advantage of the split seal design is that it allows you to install the seal with no dismantling of the pump (or equipment)—an enormous time-saver! Chesterton's split seals offer virtually leak-free performance. This leads to improved safety and environmental compliance and nearly eliminates sleeve wear, and flush water usage, among many benefits.

Featured Seal : Chesterton 442C Cartridge Split Seal

- Enhanced esign for simple installation and greater sealing reliability -

The Chesterton 442C™ Cartridge Split Seal combines superior seal performance with the ease of installation of a cartridge seal. Our patented split seal technology addresses the inherent limitations found in conventional cartridge split seal designs by

minimizing installation complications and excessive leakage. As with all split seal options, it offers easy installation and replacement without the need for teardowns.

The 442C design also offers maximum installation flexibility with its short axial length and flexible gland positioning. It simplifies split mechanical seal repair by using a standard spare parts kit, enabling you to lower your inventory costs to maintain operations.

- Design -

Patented Interlocking Face

Because the seal faces are split, the halves need to align correctly to seal. This has been one of the key problems associated with the installation of

split seals and their sealing consistency.

split seals and their sealing consistency.

The Interlocking Face eliminates this problem by uniquely keying the mating halves so that faces align correctly without having to manually work the face halves. Damage associated with handling and additional cleaning requirements are eliminated, which results in greater sealing reliability.

Self-Aligning Face Design

The 442C™ Cartridge Split Seal can be installed without checking for face alignment or touching the sealing elements—the seal faces align themselves and do not have to be handled or worked. The gland assembly is installed around the rotary without inspecting face alignment. Quicker installations and enhanced reliability are the results!

f

Spring Lifter

The 442C uses a mechanism which automatically energizes the seal faces when the gland assembly is installed. During installation, the springs are not energized, minimizing potential installation damage which can occur. Split seal reliability is enhanced!

Easy installation

The Chesterton 442C Cartridge Split Seal simplifies seal installation while also addressing sealing reliability at start-up.

With only two seal components, the 442C is easy to install and is engineered to enhance sealing reliability like no other cartridge split seal.